WE MAKE IT PERSONAL

A VARIETY OF PRODUCTS FOR MANY APPLICATIONS

STRIVING FOR OUTSTANDING RESULTS

Fireproofing

Fireproofing

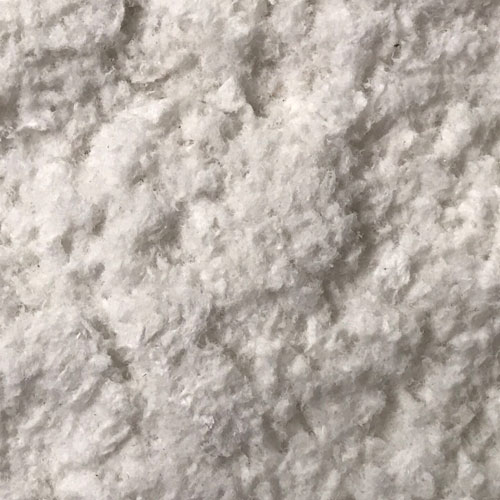

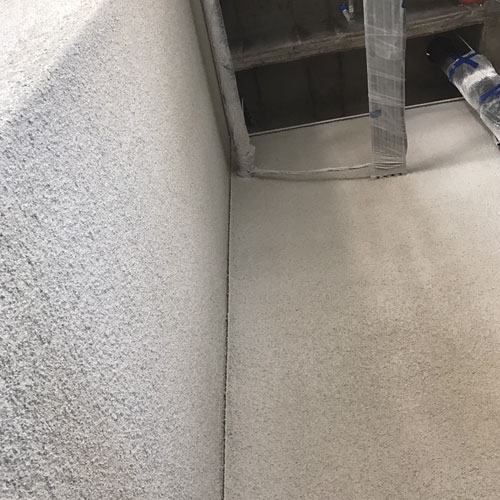

(15-21 pcf) Also known as commercial density, low density, or regular fireproofing; it is either fibrous or cementitious in composition and is the most common way to achieve fire protection rating requirements on covered or protected steel structures. It can withstand most interior weather conditions throughout the construction phase. It is used in structures less than 75 feet tall. The material is grey to dark grey and has a randomized texture but a uniform finish.

(22-39 pcf) Either a wet or dry material, medium density is designed for use in high traffic or exposed areas, though it is not intended to be interacted with. The fiber or cement based material will essentially achieve the same results as a standard density material- superior performance and exceptional durability, but with a greater density and bond strength. Exposed interior applications of spray fireproofing will provide nominal thermal and acoustic characteristics as well. It is appropriate for structures between 75-420 feet tall. The material is grey to dark grey and has a consistent texture and uniform finish.

(39+ pcf) Usually made with a wet cement binding agent, high density spray fireproofing is the hardest and most dense material for fire resistance. Counter intuitively, it does not last longer under flame than the lower densities, but it can withstand far more physical interaction with weather and humans. It can be used in exterior applications but is commonly designed for parking garages and mechanical rooms where vibration is commonplace.

Aesthetic fire protective paint for indoor or outdoor usage. Intumescent paint is perfect for architects incorporating exposed steel into their design or in assemblies where clearance is limited. The finish of these products is smooth and attractive while still achieving the fire rating requirements of your project. It can be intended for physical interaction.

Thermal Insulation

Thermal Insulation

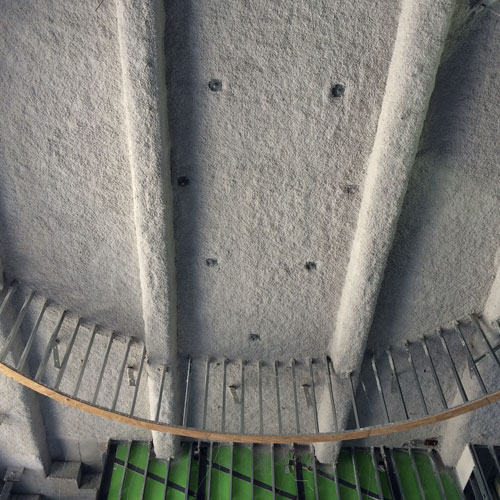

(R4 thermal value per inch) Fluffy but resilient, Monoglass is an ideal exposed exterior insulating material. It must be protected from the elements but cover up is not necessary therefore it is commonly used in soffits, bridge ways and parking garage decks. Can be applied horizontally, vertically, onto other materials and serves as an acoustic dampener.

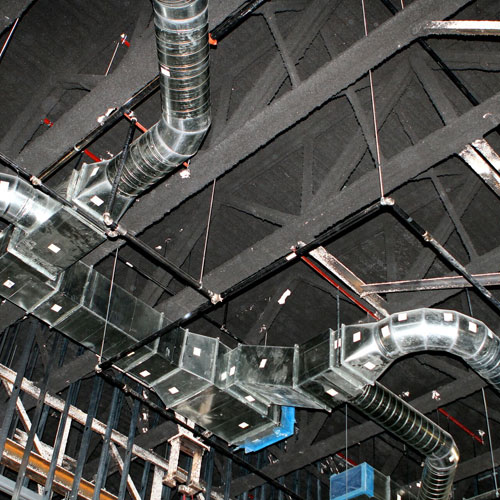

(R3.8 thermal value per inch) This premier fiber based sprayed-in-place insulation adheres to virtually all common construction materials and has great strength for a fibrous material. It can be sprayed in a single monolithic coating up to 5 inches without mechanical support thanks to its unique adhesive properties. K13 has no voids or compressed areas, which drastically reduces heat loss through the substrate. K13 can come in any color but standard pricing allows for White, Grey and Tan. The most popular color choice is Black.

(R4.5 thermal value per inch) Ure-K was created to provide a prescriptive 15 minute thermal barrier over spray foam insulation, but does more than that. In addition, this fibrous material is fire resistant for 15 minutes and boasts highly efficient sound absorbing qualities that meet OSHA Standards at just 1.25 inches.

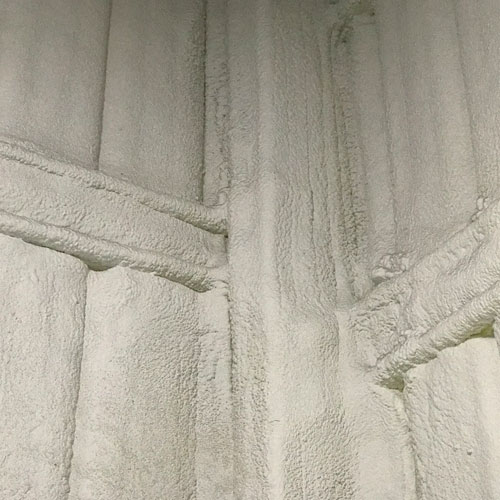

(R3.6-6.7 thermal value per inch) Spray Polyurethane Foam insulation is the most versatile insulation material on the market today. Rapid installation, seamless void fill and air tight barriers make this product an easy choice for numerous project scenarios. Foam can be used as a vapor barrier in some cases adding to the structural integrity of the build. Foam is used in crawlspaces, exterior walls, roof decks and cold floors. The material fills cracks and voids at the molecular level so construction error is mitigated. When a building optimizes its airflow containment, HVAC units run more efficiently, condensation is mitigated and the structure becomes a single sealed environment, which lowers your bills and allows for highly predictable and reliable air conditioning costs.

Accoustic Insulation

Accoustic Insulation

(NRC .5-1.0) Due to its fibrous structure, K13’s texture significantly reduces sound resonance. Ambient noise, echoes and machine resonance are greatly reduced with this material. It is commonly applied in areas with large interior volumes like auditoriums, sports facilities, detention centers, restaurants, convention halls and parking garages. The material has an elegant yet passive appearance that looks great above hanging light fixtures and bare ceilings alike. “Naturally Tough- Naturally Attractive.”

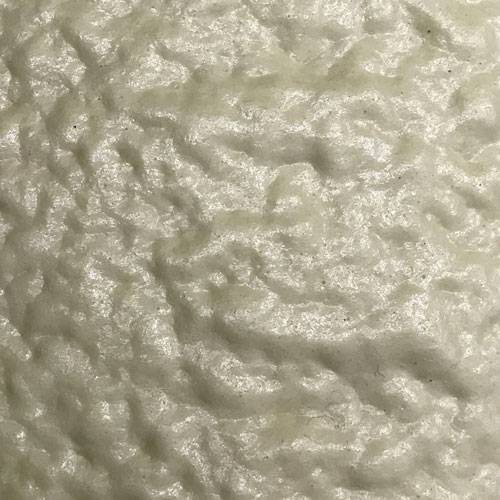

(NRC .65-.90) SonaSpray is a cellulose based product designed for high performance acoustic and lighting layouts where a finer finish is required. This product is intended to accent large spanning ceilings and modern architecture by helping distribute lighting evenly. Common applications include churches, passenger terminals, libraries, cafeterias and hotel lobbies. SonaSpray will resist impact and abrasion without cracking or spalling.

(NRC .75) SonaKrete achieves a very smooth hard finish while still retaining acoustic qualities and is used anywhere you could find drywall, plaster, or any other smooth surface. This material is designed to be trowled layer by layer for a dense finish that is smooth and free of irregularities. Where it excels is installation speed and color choice- the materials customizability allows your design team the opportunity to be creative with ceilings and walls that contribute to the room’s design theme.

Pyrok is a decorative gypsum plaster with premier sound absorption qualities and exceptional durability for contemporary and restorative designs. It is offered in a variety of textures and comes in 12 colors. You can go thin for a lush aesthetic finish or thick for high acoustical performance. Pyrok is commonly specified in event halls, churches, temples, and other large spanning ceiling spaces, as well as transportation projects, industrial facilities and exterior applications where vibrations and water infiltration are commonplace. Pyrok is also UL fire rated.

(R3.6 thermal value per inch) Open Cell Polyurethane Foam is low density expansive foam that relies on heat reaction to expand cells and fill cavities between conditioned and non conditioned spaces. Open Cell Foam is vapor-permeable therefore it will accept and release moisture when air moisture content fluctuates. Open cell is the ideal insulation choice for wooden structures’ exterior walls and underside of roof decking.

(R6.7 thermal value per inch) Closed Cell Polyurethane Foam is medium density foam that expands to create tightly packed CO2 filled cells that completely stop air and vapor transfer, and add structural support to building assemblies. Closed Cell is mostly used where a vapor barrier is desired or where the insulating cavity is too shallow for open cell. Closed Cell has greater insulating power with less material.